Guardians of Construction Skies: The Critical Role of Crane Aviation Light

In the ever-changing urban landscapes where construction cranes punctuate skylines, a silent but crucial safety system operates tirelessly—the crane aviation light. These specialized warning devices serve as essential visual markers, protecting both low-flying aircraft and ground personnel from potential collisions. As construction projects reach increasingly impressive heights, particularly in densely populated urban areas, the importance of effective crane aviation light systems has never been more critical. This article examines the technical specifications, regulatory requirements, and innovative technologies that define modern crane lighting solutions.

The Imperative of Aerial Visibility

The primary function of crane aviation light systems is to ensure that these temporary yet massive structures are clearly visible to aircraft, particularly helicopters engaged in emergency services, news reporting, or law enforcement operations. Unlike permanent structures, cranes present unique challenges due to their temporary nature, variable heights, and often urban locations where background lighting can obscure visibility. Effective crane aviation light systems must provide unambiguous visual warnings that can be immediately recognized and understood by pilots operating in complex airspace.

Regulatory Framework and Compliance Standards

The installation and operation of crane aviation light systems are governed by strict aviation safety regulations established by authorities such as the Federal Aviation Administration (FAA) in the United States and the European Aviation Safety Agency (EASA) in Europe. These regulations typically mandate:

Height-Based Requirements: Specific lighting obligations triggered when a crane exceeds certain height thresholds above ground level or surrounding structures

Light Intensity Specifications: Defined intensity levels (low, medium, or high) based on the crane's location relative to airports and flight paths

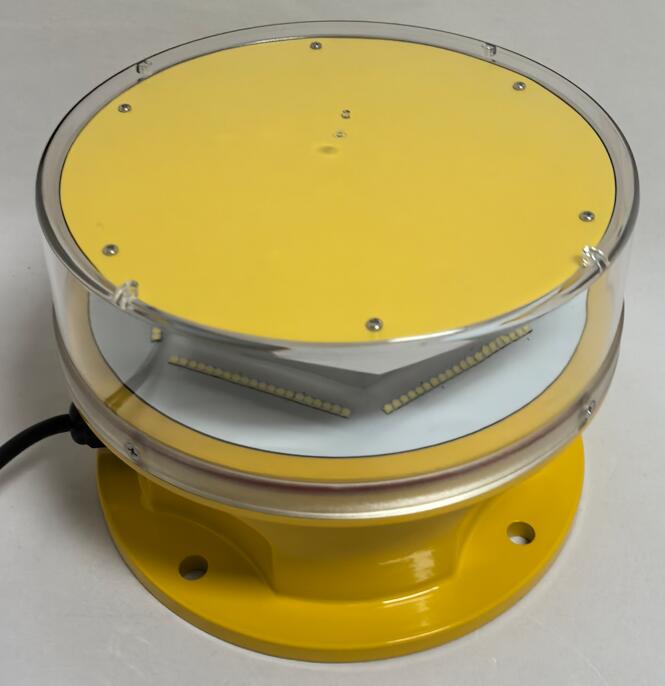

| crane aviation light |

Placement Protocols: Requirements for multiple lights positioned at the highest points of the boom and jib to ensure 360-degree visibility

Operational Characteristics: Standardized flash patterns and colors (typically red) to distinguish crane lights from other aerial illumination

Compliance with these regulations is not optional—it represents a fundamental responsibility for construction companies and crane operators to ensure airspace safety.

| crane aviation lights |

Engineering for the Construction Environment

Crane aviation light systems must be engineered to withstand the exceptionally challenging conditions of construction sites:

Durability Requirements: Housing constructed from high-impact materials capable of resisting vibration, weather exposure, and potential impacts from debris

Environmental Sealing: Advanced ingress protection (typically IP65 or higher) against dust, moisture, and extreme temperature fluctuations

Power Autonomy: Solar-powered units with efficient energy storage systems that can operate for extended periods without sunlight exposure

Vibration Resistance: Specialized mounting systems and component designs that maintain operational integrity despite constant crane movement and wind-induced motion

Technological Evolution in Crane Lighting

Modern crane aviation light systems have benefited significantly from technological advancements:

LED Revolution: Light Emitting Diode technology has transformed crane lighting with its superior energy efficiency, extended lifespan, and enhanced resistance to vibration and shock

Smart Monitoring Systems: Wireless connectivity enables real-time status monitoring, automatic fault reporting, and remote performance verification

Adaptive Intensity Control: Photosensitive sensors that automatically adjust light output based on ambient conditions, optimizing visibility while conserving energy

Modular Design: Quick-disconnect components and tool-less maintenance features that minimize downtime and reduce service requirements

Implementation Best Practices

Successful crane aviation light deployment involves careful planning and execution:

Site-Specific Risk Assessment: Evaluation of local air traffic patterns, surrounding infrastructure, and environmental factors

Redundancy Planning: Installation of backup systems to ensure continuous operation in case of primary system failure

Documentation and Compliance Tracking: Maintaining detailed records of installations, maintenance, and regulatory compliance

Pilot Notification Procedures: Coordinating with local aviation authorities to ensure proper documentation of temporary airspace obstructions

The Future of Crane Safety Lighting

Emerging technologies are shaping the next generation of crane aviation light systems:

Integrated Drone Detection: Systems that can detect approaching drones and adjust lighting patterns to enhance visibility for unmanned aircraft

Advanced Materials: Development of lighter, more durable composites that reduce weight while maintaining protection

Predictive Maintenance: AI-driven systems that can anticipate maintenance needs before failures occur

Enhanced Sustainability: Improvements in solar efficiency and battery technology that extend operational autonomy

Conclusion: Elevating Safety Standards

The crane aviation light represents far more than regulatory compliance—it embodies the construction industry's commitment to safety and responsibility. These systems form a critical link in the chain of aerial safety measures, protecting lives and property while enabling the continuous development of our urban environments. As construction technologies advance and cities continue to grow vertically, the role of crane aviation light systems will remain essential in maintaining safe separation between ground operations and aerial activities. Their persistent red glow against the night sky serves as a constant reminder of the industry's dedication to safety and innovation, ensuring that progress in construction never comes at the expense of aerial safety.