Aircraft Warning Light Price: Factors Influencing Cost and Smart Purchasing Tips

Aircraft warning lights are critical safety devices installed on tall structures like towers, wind turbines, and buildings to prevent collisions with low-flying aircraft. Their price varies significantly depending on multiple factors, making it essential for buyers to understand what influences cost and how to make a cost-effective purchase.

Key Factors Affecting Aircraft Warning Light Price

1. Light Type and Technology

Aircraft warning lights come in different types, primarily categorized as:

Low-intensity lights (L-810, L-864) – Suitable for structures below 150 meters.

Medium-intensity lights (L-864, L-865) – Used for structures between 45 and 150 meters.

High-intensity lights (L-856, L-857) – Required for structures exceeding 150 meters.

LED-based lights are more expensive than incandescent or halogen variants but offer longer lifespans and lower maintenance costs.

| Aircraft Warning Light Price |

2. Compliance with Aviation Regulations

Lights must meet strict standards set by organizations like the FAA (Federal Aviation Administration), ICAO (International Civil Aviation Organization), and local aviation authorities. Certified products often cost more due to rigorous testing and quality assurance.

3. Power Supply and Installation Requirements

Solar-powered lights are pricier upfront but reduce long-term electricity costs.

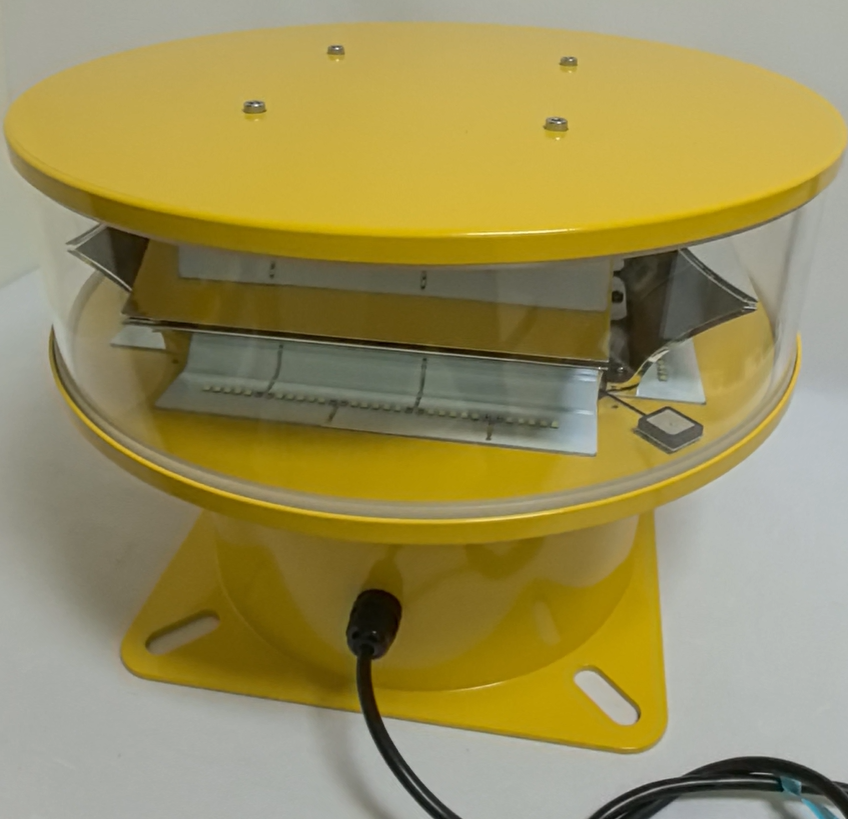

| Aircraft Warning Light |

Hardwired systems may require additional infrastructure, increasing installation expenses.

Dual-power systems (solar + battery backup) add to the initial cost but enhance reliability.

4. Durability and Weather Resistance

Lights designed for extreme weather conditions (high winds, heavy rain, or freezing temperatures) typically cost more due to reinforced materials and advanced sealing technologies.

5. Brand and Manufacturer Reputation

Established brands like Orga, Hughey & Phillips, and TWR Lighting often charge premium prices due to their proven reliability and warranty support.

Smart Purchasing Tips to Optimize Aircraft Warning Light Price

1. Assess Your Specific Needs

Determine the required light intensity based on structure height.

Check if flashing or steady lights are mandated by local regulations.

2. Compare Total Cost of Ownership

LED lights may have a higher upfront cost but lower long-term expenses.

Solar-powered options eliminate electricity bills but require periodic battery replacements.

3. Verify Compliance and Certification

Ensure the product meets necessary aviation standards to avoid fines or replacement costs later.

4. Consider Maintenance and Lifespan

Opt for models with easy-access components for quick servicing.

Check warranty terms to avoid unexpected repair costs.

5. Bulk Purchasing and Supplier Negotiation

If multiple units are needed, suppliers may offer discounts. Comparing quotes from different vendors can help secure the best aircraft warning light price.

The aircraft warning light price depends on technology, compliance, durability, and brand reputation. Buyers should evaluate their specific needs, compare long-term costs, and ensure regulatory compliance to make an informed purchase. Investing in high-quality, certified lights ensures safety, reduces maintenance costs, and avoids regulatory penalties.

By understanding these factors, businesses and infrastructure developers can optimize their budget while maintaining aviation safety standards.